Product Introduction

Monorail cranes are most effective in production applications where materials are repetitively moved from one point to another. The monorail hoist and trolley run on a single stationary beam, normally include H-beam or I-beam.

Examples include assembly operations, transport of materials to workstations and lines where parts are blasted, painted or coated. Monorails also serve as a material handling alternative in places that cannot accommodate a bridge crane.

Features

- Improve labor efficiency

- Safe and reliable brake

- Long service life

- Maintenance is convenient

- Use a safe

- Light weight

More Details

Fixed Monorail Hoist

Straight Monoral Crane

Annular Monorail Crane

S Type Monorail Crane

Wire Rope Hoist

Electric Chain Hois

European Type Hoist

Travelling Monorail Crane with Travel Mechanism

H Beam & I Beam for Monorail Hoist

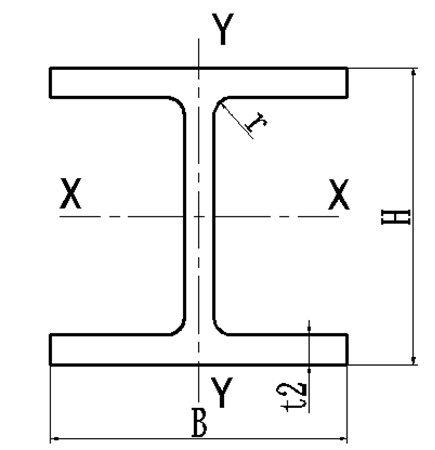

Some Specification of H Beam(According to practical choose different model)

| Type | ModelHeight*Width | Section Size mm | Section Areacm2 | Weightkg/m | |||

| H*B | t1 | t2 | r | ||||

| HW | 100*100 | 100*100 | 6 | 8 | 10 | 21.9 | 17.2 |

| 125*125 | 125*125 | 6.5 | 9 | 10 | 30.31 | 23.8 | |

| 150*150 | 150*150 | 7 | 10 | 13 | 40.55 | 31.9 | |

| HM | 150*100 | 148*100 | 6 | 9 | 13 | 27.25 | 21.4 |

| 200*150 | 194*150 | 6 | 9 | 16 | 39.76 | 31.2 | |

| 250*175 | 244*175 | 7 | 11 | 16 | 56.24 | 44.1 | |

| HP | 200*200 | 200*204 | 12 | 12 | 16 | 72.28 | 56.7 |

| 250*250 | 250*252 | 14 | 14 | 16 | 82.05 | 64.4 | |

| 300*300 | 300*305 | 15 | 15 | 20 | 135.4 | 106 | |

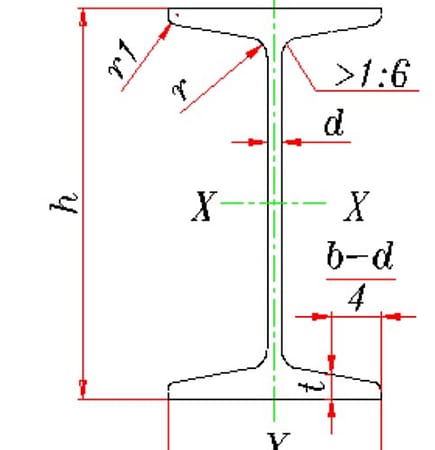

Some Specification of I Beam(According to practicl choose different model)

| Type | Size mm | Section Areacm2 | Weight kg/m | |||||

| h | b | d | t | r | rl | |||

| 12.6 | 126 | 74 | 5 | 8.4 | 7.0 | 3.5 | 18.118 | 14.223 |

| 14 | 140 | 80 | 5.5 | 9.1 | 7.5 | 3.8 | 21.516 | 16.890 |

| 16 | 160 | 88 | 6.0 | 9.9 | 8.0 | 4.0 | 26.131 | 20.513 |

| 18 | 180 | 94 | 6.5 | 10.7 | 8.5 | 4.3 | 30.756 | 24.143 |

| 20a | 200 | 100 | 7.0 | 11.4 | 9.0 | 4.5 | 35.578 | 27.929 |

| 20b | 200 | 102 | 9.0 | 11.4 | 9.0 | 4.5 | 39.578 | 31.069 |

| 22a | 220 | 110 | 7.5 | 12.3 | 9.5 | 4.8 | 42.128 | 33.070 |

| 22b | 220 | 112 | 9.5 | 12.3 | 9.5 | 4.8 | 46.528 | 36.524 |

| 25a | 250 | 116 | 8 | 13 | 10.0 | 5.0 | 48.541 | 38.105 |

| 25b | 250 | 118 | 10 | 13 | 10.0 | 5.0 | 53.541 | 42.030 |

Client Care

You might be interested in the following questions

-

1. Whether you can offer customized Wire Rope Electric Hoist?

Yep, of course, we are a manufacturer, and we have our own engineer group. They can work out customized design according to your requirement. The most important thing is that you tell all the needed information.

-

2. What's information shall we offer to get precise quotation & best design?

- Max lifting capacity: ___ton?

- Lifting height (hook center to ground):___m?

- Any special requirement on lifting speed?

- Lift what:?

- Power supply: 380V/50HZ/3Ph is ok?

- Working frequency: like how many working times/day, hours/time?

-

3. What's the advantage of your product?

- Products for the outer packing all adopt code printer to print the product code and the company name, every batch of products will be found by number.

- All hoists will oiling before delivery.

- Hoist stop plate and conductive base frame all process by punch, with beautiful appearance and unified size.

- The bearing Increased oil seal device, to prevent dirt enter, prolong service life.

- Paint adopt a high temperature resistant paint, fixed position increase prefix and spraying number mark, both to ensure the product quality and easy installation.